Acquisition of ISO9001 & ISO14001 Certification

FUJII DENKO working on quality control and quality assurance acquired the Quality Management System (ISO 9001) certification in 2000 (Scope of Certification: Activities related with design and development, production and sales of personal fall-arrest systems,work positioning systems, fall arresters and construction machines used for power distribution, electric supply and telecommunication wires). In addition, we acquired the Environmental Management System (ISO 14001) certification in 2005 considering the global environment (Scope of Certification: Activities related with design and development, production and sales of personal fall-arrest systems,work positioning systems, fall arresters and construction machines used for power distribution, electric supply and tele-communication wires).Head Office / Takino Factory

Based on our endless pursuit of safety and quality, we carry out production and quality control from planning and designing.

The consistent production system from development and production to quality control in blessed natural environment

Kamitakino, Hyogo prefecture where FUJII DENKO’s head office and Takino factory are located is in tranquil natural environment surrounded by rich greenery. This location is a truly grateful environment for companies providing “Safety”. Rather than working in a hustle and bustle of a city, developing and manufacturing products in relaxing environment where can be felt close to nature can achieve higher level safety. Our products affect human lives and are required responsibility to protect all users’ safety. Therefore, under our consistent production management and quality control from research development and mold making to processing and assembly, we manufacture high-quality products providing safety.

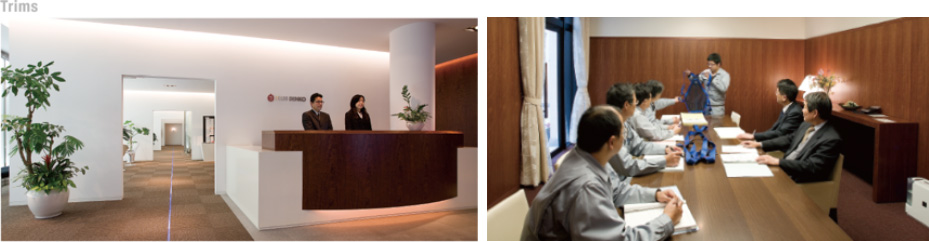

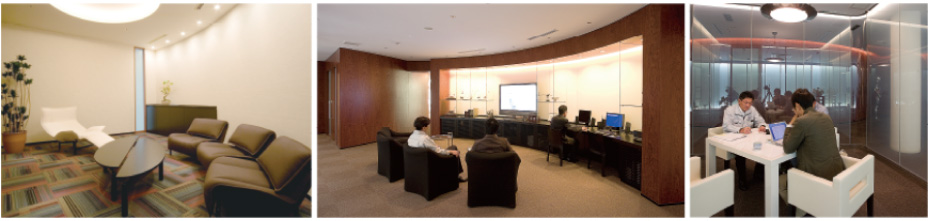

Not “a place for business negotiation” but “a place to communicate safety”. TRIMS is where visitors can enjoy a meal and conversation in a relaxed mood.

For FUJII DENKO supplying products to protect human lives, it is important to get many people reaffirm the meanings of the word “Safety”. And listening to thoughts about safety from customers is also important. In order to convey this feeling, we set up Trims in the head office and Izums on Yashiro factory site as not “places for business negotiation” but “places to communicate safety”. It can be used for various purposes such as meeting room, panel discussion using an 80-inch LCD panel, and comfortable guest room for visitors with internet access. Izums is also effectively used as a welfare facility and brings comfort to the work environment as refresh and communication space.

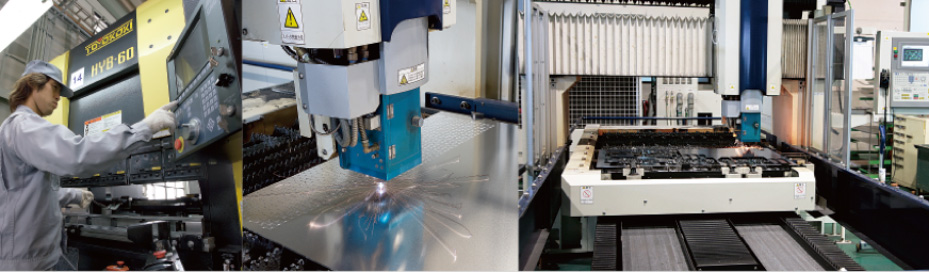

Takino Factory with production facilities using the latest automation equipment.

Takino No. 1 and No. 2 divisions which started operation in 1988 are in charge of metal material pressing, welding, finishing, and mold making processing, and they manufacture high-quality products quickly by using the latest factory automation technology, automation equipment, and high-technology machine tools. No. 3 and No. 4 divisions which started operation in 1989 are in charge of assembling of construction equipment for electric power and tele-communication, and rail or wire type fall arresting systems. Robots are introduced in the pressing and welding processes to produce homogeneous products safely and quickly. We improve the efficiency by utilizing 3D automated warehouses, mobile racks, conveyor systems, and many other FA equipment. As a general flow of the product completion, processing for metal materials is performed at this Takino factory, and the final process focused on assembly is performed at Yashiro factory.

Yashiro Factory

Yashiro factory boasting beautiful rich green environment. Delicate processes that can only be performed by hand bring life to products.

Our strict quality control and sincere processes by handwork support the quality and reliability of FUJII DENKO brand.

Yashiro factory is located in a corner of spacious countryside and consistently perform work processes from rope production and belt sewing to testing for finished safety belts. Mechanization for efficiency is proceeding in many industrial fields nowadays, but in FUJII DENKO brand products which are responsible for human lives, not all production lines are mechanized. Especially there are many processes that can only be performed by handwork such as belt sewing and rope splicing at Yashiro factory. These require the craftsmanship developed for many years and gain reliable quality unique to handwork.